A recent research project of the Technical University of Berlin (TU Berlin) aimed to develop a method for predicting the friction coefficient on the road. To achieve this, the team of the university’s automotive engineering section carried out extensive braking tests. For this, an important technical aid from Lufft mustn’t be left out.

What influences friction on surfaces the most?

Opinions about what influences friction tend to vary extremely: Up to now, there is neither a general algorithm for determining the friction coefficient by means of sensor technology nor sufficient knowledge about the decisive influencing factors, e.g. intermediate layer, tires, or road surfaces. The ultimately most important factors, haven’t yet been explored sufficiently.

We have taken this as an occasion to start our project with the aim to determine a method for predicting the friction between tire and road.

The experimental setup

In a period of 30 months, approximately 3,600 brakes were carried out at 32 different, defined measuring spots. They were located in the city, on country roads and motorways south-west of Berlin. The route had a total length of 121 km. Out of these test drives, 938 measurements were finally used and compared with nearby ice alert or weather stations. For this purpose, we digitally stored the road and tire data before carrying out the braking measurements. Then we determined the location by using GPS data.

Other important information was the ambient temperature, vehicle speed and rain intensity supplied by the car. The vehicle deceleration was measured by means of a servo acceleration sensor every 0.5 seconds. Through this, the friction coefficient could be calculated.

Another important tool was the mobile road sensor MARWIS from Lufft providing additional weather data for comparison. In addition, it provided reliable information about the intermediate layer, which served as a good reference for our own friction test by means of braking.

Data collection

By means of the many braking tests we were able to create a spectrum of all possible road weather conditions – at different water films, on closed snow covers, on slush, at all possible surface temperatures as well as for dry road surfaces. Each measurement data set finally contained over 60 parameters consisting of information on weather, vehicle-specific and road surface, which were only partially taken into account of the algorithm development.

The fusion of all recorded information helped us to determine the estimation process of the prevailing friction.

The result

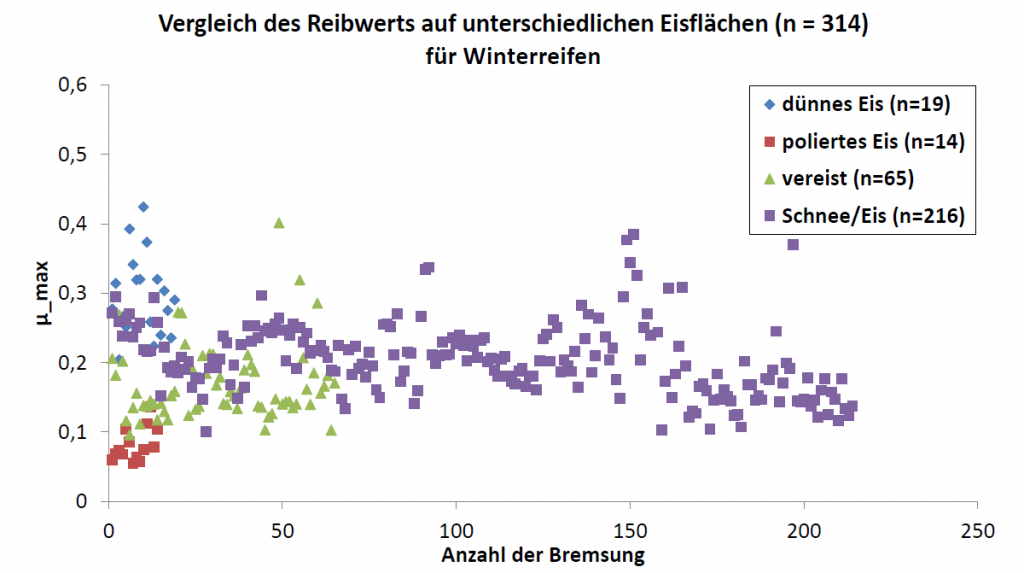

The extensive experiment showed that the intermediate layer between road and car tire is the most important influencing factor for the friction coefficient. This complies with the MARWIS friction calculation. For dry surfaces, we observed the maximum friction coefficient of up to 1.05. In the case of thinly iced surfaces, the value was between 0.2 and 0.45. On glazed frost, the friction values were between the absolute lowest value of 0.04 and 0.15. The friction coefficient was between 0.1 and 0.4 when the surface was icy. On snow it fluctuated between 0.15 and 0.4.

The complexity of the many possible influencing factors can thus be reduced quite well to just what is between the road and the tires. Therefore the research project confirmed, among other things, that the innovative sensor MARWIS serves as a good reference for (road) weather data and especially for the friction value which is influenced by the intermediate layer in form of snow, ice and water.

You want to know more about the mobile sensor MARWIS or want to request a quote? Check our landing page on the award-winning mobile road sensor MARWIS or directly get in touch with our team.