For utility-scale PV plants the Performance Ratio (PR) is an important indicator of the efficiency of all the components used. Factors like solar irradiance, PV module temperature, module orientation, module cleanliness; all the way down the chain to cables, connectors, DC and AC power (inverter performance). All of these have their influences on the real energy output compared to the ideal maximum possible output that gives one the PR.

IEC 61724-1 published in March 2017 covers every aspect of Photovoltaic System Performance Monitoring for 3 classes; High Accuracy (A), Medium Accuracy (B) and Basic Accuracy (C). It is becoming the guideline for many EPC’s to plan plant monitoring and to prove that they comply with the recommendations set out.

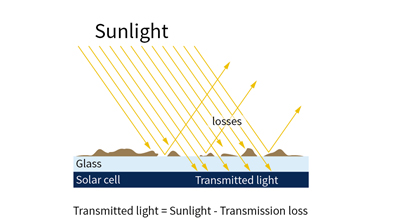

Even though soiling loss was known to be a big influencer on power production it wasn’t included in the original 1998 version of the standard. But, it makes sense to take it into account as the first energy loss encountered in a PV system is caused by soiling on the module glass that prevents solar radiation (=energy) reaching the solar cells. Dust and dirt on the PV modules, and the associated loss of power production, was an important ‘unknown’ in PR calculation.

Important ‘unknown’ in PR calculation

Now, the 2017 standard includes soiling ratio (SR) measurement as mandatory for Class A monitoring if the soiling losses are expected to be > 2 % and optional for Classes B and C. The data should be recorded every minute and the minimum number of monitoring points is related to plant power capacity.

The technology and methodology described in  the standard are based on the solutions available at the time when the document was being prepared, just before Kipp & Zonen launched DustIQ.

the standard are based on the solutions available at the time when the document was being prepared, just before Kipp & Zonen launched DustIQ.

The described solutions have two identical PV devices, preferably PV modules identical to those in the array to be monitored and mounted in a similar way. One device is allowed to become dirty and is the ‘soiled reference’ and the other must be regularly kept free of soiling as the ‘clean reference’. The clean device must be heated to remove frozen precipitation (frost, etc.).

Extra equipment is needed to measure short-circuit current, maximum power and the PV device temperatures. One needs to calibrate the setup under a known condition, usually STC (Standard Test Conditions) before one can start taking actual measurements. Calibration shall be done at least annually.

The accuracy of the measurement relies on having detailed information about the PV devices used; temperature dependency of current, voltage and power; to name just a few. Another important factor is that soiling of the ‘clean reference’ device will significantly influence the SR calculation and will show a higher (=better) soiling ratio than it should. This is especially important in areas with fast soiling build-up where very frequent cleaning of the device might be needed. There are also sunlight response dependencies such that IEC 61724-1 states that it may be advisable to only use measurement data from 2 hours each side of solar noon.

To deal with these inherent drawbacks, purely optical and maintenance-free alternatives have been developed and brought to market. These new systems are smaller, lighter, simpler, more affordable and allow for multiple measurement points; including right in between the PV modules.

Soiling distribution is not uniform across a PV plant and being able to measure at several points in the park allows a soiling map to be created and enables outliers to be recognised, together with providing redundancy. Having the measurement point between PV modules makes sure that the soiling monitor receives the same soiling and the same cleaning as the modules around it.

The purely optical approach takes away the dependency on solar light for the soiling measurement; and current, power and temperature monitoring are not needed to calculate the SR. The Kipp & Zonen DustIQ with its Optical Soiling Measurement (OSM) technology measures every minute, 24/7, with or without sun. It is a simple 5-minute procedure to calibrate the DustIQ on site to suit the local dust profile.