Accurate irradiance data is the backbone of solar project performance, bankability, and long–term investor confidence For EPCs, it shapes everything from yield assessments and energy modeling to commissioning acceptance tests and contractual guarantees. But this reliability depends on a critical assumption: the irradiance measurements used to validate performance are accurate.

Even the most advanced pyranometers are exposed to environmental, mechanical, and user-induced influences that introduce error. Understanding these sources, and controlling them during design and construction, helps EPCs minimize uncertainty, avoid avoidable PR disputes, and safeguard their reputation for technical excellence.

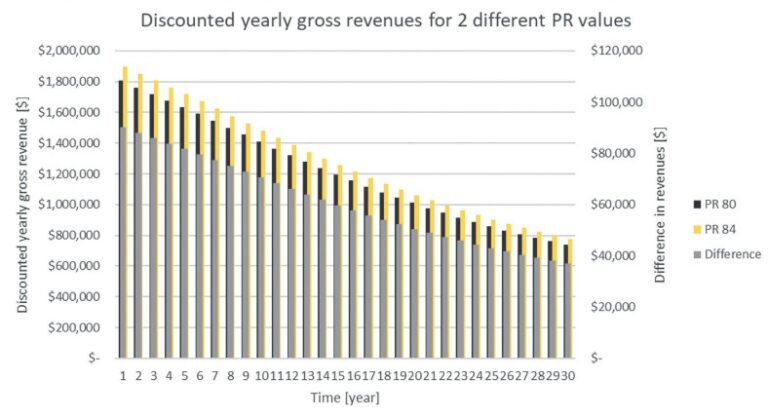

Why Small Measurement Errors Create Big Financial Impacts

A small deviation in irradiance accuracy can translate into major financial consequences over the life of a PV plant. For example, a 4% Performance Ratio (PR) deviation at a 64 MW site can result in more than $1.8 million in lost revenue over 30 years. Even fractional errors can cascade into issues like:

- Missaligned performance guarantees

- Unexpected EPC warranty exposure

- Incorrect Yield model validation

- Faulty Investor reporting

- Poor SCADA ‑based operational decisions

For EPCs, irradiance accuracy is not just a technical requirement – it’s a risk management imperative.

Manufacturer Related Sensor Errors: The Baseline EPCs Must Understand

Modern ISO 9060:2018 Class A pyranometers have significantly reduced design intrinsic uncertainty, and innovation for over nearly a century. With quartz domes, fast response thermopiles, digital temperature compensation, and improved calibration methods, pyranometers have pushed irradiance accuracy closer to physical limits. Still, several baseline error sources remain

- Directional / Cosine Response

Sensors do not respond equally to all angles of incoming radiation. Errors are highest at low sun angles, precisely the conditions where siting and alignment mistakes compound.

- Spectral Error

Changes in the solar spectrum (clouds, aerosols, humidity) interact with sensor materials. Quartz domes minimize this, but EPCs should still expect slight variations under unusual atmospheric conditions.

- Temperature Coefficient

All thermopile pyranometers drift slightly with temperature. High quality instruments compensate electronically, but they cannot fully eliminate this behavior.

- Nonlinearity

At the extremes of irradiance (very low or very high), output voltage does not scale perfectly with input light.

- Calibration Uncertainty & Long- Term Drift

Even ISO accredited calibrations include small uncertainty margins, and sensors naturally drift over years. EPCs should account for recalibration schedules in project documentation.

Together, these form the baseline uncertainty EPCs need to factor into PR guarantees and model assumptions.

User Induced Errors: The Most Common, and Most Preventable Source of EPC Measurement Issues

Field research consistently shows that installation and handling errors contribute to more uncertainty than the sensor itself. These errors are fully within EPC control.

- Soiling

Dust, pollen, bird droppings, and construction debris all reduce irradiance transmission. Even short‑term soiling can skew early PR measurements.

- Leveling & Tilt Misalignment

A pyranometer intended for GHI must be perfectly level.

A POA sensor must match the module tilt within <0.5°.

A single degree of misalignment can create up to 20% relative error at low sun angles, large enough to trigger false underperformance claims.

- Improper Siting & Placement

Incorrect placement, edge rows, atypical modules, or inconsistent tracker positions, can introduce up to 7.6% variability across the same site.

EPCs should standardize siting rules before construction begins.

- Shading

Cable trays, conduit, tracker motors, combiner boxes, or even temporary construction infrastructure can cast micro‑shadows that distort PR.

- Dew & Frost

Cold morning dew increases diffuse radiation, temporarily inflating readings. Heated domes prevent this effect and improve early‑day data.

- Mechanical Shock or Transport Damage

Sensors mishandled during construction, shipping, or installation can develop small internal misalignments not visible to the eye – yet impactful.

Environmental & Operational Influences EPCs Should Expect

Even with perfect installation, natural conditions can temporarily affect pyranometer output:

Rapid Temperature Changes- Thermopile sensors rely on heat flow, making them sensitive to strong temperature gradients.

Atmospheric Spectral Shifts –Clouds, aerosols, or wildfire smoke alter spectral distribution; even spectrally flat sensors are not immune.

Wind Effects – While domes protect the detector, strong gusts can still influence temperature differentials.

High quality pyranometers mitigate these effects, but EPCs should recognize that environmental variability is inherent to solar measurement .

How EPCs Can Reduce Pyranometer Error

The most effective strategies are neither expensive nor complex, they simply require consistency, planning, and quality control.

✔ Specify the Right Accuracy Class

Choose ISO 9060:2018 Class A pyranometers. These reduce design intrinsic uncertainty to the lowest practical levels and should be standard for bankable EPC projects.

✔ Install with Precision

- Level GHI sensors using bubble levels accurate to 0.1°

- Match POA tilt precisely to module tilt (<0.5°)

- Avoid edge rows and non‑representative modules

- Route cables and conduit to avoid any shading risk

✔ Maintain Throughout Construction & Commissioning

- Keep domes clean (dust, paint spray, construction dirt)

- Inspect for accidental shading from temporary structures

- Verify alignment regularly, especially on trackers

- Document calibration dates and plan for long‑term recalibration

✔ Use Heating or Ventilation Where Climate Requires It

Integrated dome heaters prevent dew/frost bias in cold or humid climates.

✔ Validate Data Early

Unexpected patterns during commissioning often indicate siting or installation issues, not sensor flaws.

These steps cost little, but they significantly reduce uncertainty and help EPCs hand over a plant with fully validated, high quality irradiance data.

Why This Matters for EPC Project Success

Well-designed and well-installed irradiance measurement systems:

- Protect EPCs from disputes during commissioning

- Reduce the risk of PR guarantee claims

- Strengthen investor confidence and model credibility

- Ensure that any future underperformance can be correctly attributed

Simply put: accuracy today prevents costly conversations tomorrow.

Conclusion: Accuracy Is a Shared Responsibility

Manufacturers have spent decades reducing intrinsic sensor limits, but EPCs exert the greates influence on real world irradiance accuracy. By applying proper siting, installation discipline, and environmental awareness, EPCs can ensure that pyranometer data reflects true onsite conditions, supporting fair PR validation, reliable yield modeling, and longterm project success.

Ready to see these strategies in action? Download the visual guide to optimizing pyranometer accuracy and boosting your solar project’s performance.